Cummins QSB6.7 Engine for Komatsu HX20 UGHR Haulage

The Komatsu HX20 underground hard rock haulage vehicle is a compact and highly efficient solution tailored for underground mining operations. Designed to handle confined spaces and steep gradients, the HX20 offers reliable material transport with superior performance.The vehicle has a payload capacity of 20000 kg and is mainly powered by a Cummins QSB6.7 engine with a main power of 260 HP and a torque of 2300 rpm.

As part of EMAC, ConeMac provides industrial power pack solution that integrated with air intake, air exhaust, cooling system, control system, transmission and hydraulic accessories, We also supplying special products such as explosion proof engine, generator and water pump set, as well as ultra-low temperature condition engine power pack.

We provide full life cycle services for all customers, from design to power system supply, from installation to commissioning, from after-sales service training to spare parts supply, from trouble shooting to overhaul technical support.

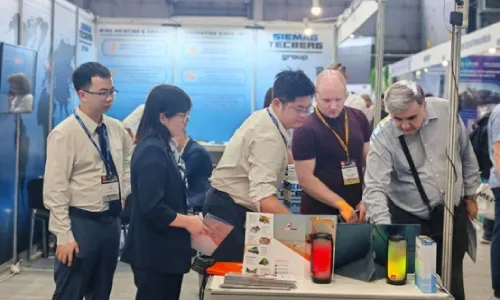

EMAC Group Participates in Automechanika Istanbul Exhibition in Istanbul

As one of the largest automotive events in the world, the Automechanika Istanbul Show attracts exhibitors and visitors from across the globe. Our Company is excited to showcase its latest products and services at the event, which will provide an excellent opportunity to network with industry professionals and connect with potential customers.

EMAC Customer Interview-Thailand Engineering Company

A Promise is A Promise, EMAC always do what we say, and for customer’s feedback, also 100% original from clients’s real words. EMAC, a Chinese company that you can trust !

EMAC Customer Interview-Indonesia Shipyard

A Promise is A Promise, EMAC always do what we say, and for customer’s feedback, also 100% original from clients’s real words. EMAC, a Chinese company that you can trust!

Identification and Classification Report for Air Transport of Goods

Advantages of Cummins QSB6.7

-

Efficient combustion technology: Cummins engines use advanced fuel injection and combustion technology to provide higher fuel efficiency and reduce emissions.

-

Emission control technology: Cummins is an industry leader in emission treatment (such as EGR, SCR, DPF, etc.) and can meet the world’s most stringent emission standards (such as China VI and Euro VI).

-

Intelligent control system: Cummins engines are equipped with electronic control units (ECUs) that can monitor and optimize engine performance in real time.

-

Reliability: Cummins engines are known for their ruggedness and ability to operate in a variety of harsh environments, including high temperatures, high altitudes and extreme cold conditions.

-

Durability: High-strength materials are used in components to extend service life while requiring low maintenance.

Technical Specifications

| UGHR Haulage Model: |

HX20 |

| Engine Model: | Cummins QSB6.7 |

| Rated Power: | 260 HP |

| Rated Speed: | 2300 RPM |

| Tramming Capacity: | 20000 kg |

| Standard Box Volume: | 7.5 – 12.5 Meters³ |

| Height,Laden: |

2555 Millmeters |

| Aspiration Method: | Turbocharged & Air-Air Intercooler |

| Emission Standard: | Euro Stage III |

| Bore * Stroke: | 107 mm * 124 mm |

| Wet Weight: | N/A |

| Lead Time: | 15 – 30 Working Days |

| Payment Terms: | T/T,L/C |

UGHR Haulage Model |

Engine Model |

Engine Brand |

Rated Power |

Rated Speed |

| HX20 |

QSB6.7

|

Cummins | 260 HP | 2300 RPM |

| ——END—— | ||||

General Infomation of Cummins QSB6.7-C260 Engine |

|||

| Engine Model | QSB6.7-C260 | Bore * Stroke | 107 mm *124 mm |

| Curve&Datasheet | FR94287 | Displacement | 6.7L |

| Compression Ratio | 17.3 : 1 | Rated Power | 260 HP @ 2200 RPM |

| No. Of Cylinders | 6 Cylinders | Peak Torque | 990 N.m @ 1500 RPM |

| Fuel System | HPCR | Configuration | D313013CX03 |

| Aspiration | Turbocharged & Air-Air Intercooler | Packing Size(L * W * H) | N/A |

| ——END—— | |||

Performance Data Rated Power of Cummins QSB6.7-C260 Engine |

|||||

| Rated Power | Torque Peak | Rated Power | Torque Peak | ||

| Engine Speed | 2200 RPM | 1500 RPM | Heat Rejection to Coolant | 84 kW | 64 kW |

| Gross Power Output | 194 kW | 155 kW | Radiator Coolant Flow | N/A | N/A |

| Torque | 842 N.m | 990 N.m | Heat Loss to the Intercooler | 30 kW | 19 kW |

| Inlet Air Flow | 885 L/s | 634 L/s | Turbo Comp. Outlet Pressure | 181 kPa | 173 kPa |

| Air Flow After Pressurization | 1144 kg/min | 820 kg/min | Turbo Comp. Outlet Temperature | 163 °C | 158 °C |

| Exhaust Gas Flow | N/A | N/A | Fuel Flow | 46.1 kg/hr | 35.5 kg/hr |

| Exhaust Gas Temperature | 698 °C | 694 °C | |||

System Technical of Cummins QSB6.7-C260 Engine |

||

| Performance Data | Maximum Low Idle Speed | 1200 RPM |

| Minimum Low Idle Speed | 600 RPM | |

| Minimum Engine Speed For Full Load Sustained Operation | 1600 RPM | |

| Air Intake System | Maximum Allowable Air Temperature Rise Over Ambient At Intake Manifold | 17 delta deg C |

| Exhaust System | Maximum Exhaust Back Pressure | 10 kPa |

| Recommended Exhaust Piping Size (Inner Diameter) | 75 mm | |

| Cooling System | Maximum Intake Manifold Temperature At 25 Deg C (77 F) Ambient | 60 deg C |

| Maximum Allowable Pressure Drop Across Charge Air Cooler And Oem Cac Piping | 13.6 kPa | |

| Maximum Intake Manifold Temperature Differential (Ambient to IMT) (IMTD) | 35 delta deg C | |

| Intake Manifold Temperature For Full Fan-ON | 43 deg C | |

| Maximum Coolant Temperature For Engine Protection Controls | 114 deg C | |

| Maximum Coolant Operating Temperature At Engine Outlet (Maximum Top Tank Temp) | 107 deg C | |

| Lubrication System | Nominal Operating Oil Pressure——Minimum Low Idle | 69 kPa |

| Nominal Operating Oil Pressure——Maximum Rated Speed | 380 kPa | |

| Minimum Engine Oil Pressure For Engine Protection Devices——Minimum Low Idle | 52 kPa | |

| Fuel System | Fuel Cooling Requirements (With Diesel Fuel) | N/A |

| Maximum Heat Rejection To Return Fuel At Maximum Coolant And Inlet Fuel Temperature | 1 kW | |

| Fuel Return Flow Rate Of | 98 kg/hr | |

| Maximum Supply Fuel Flow | 205 kg/hr | |

| Maximum Return Fuel Flow | 126 kg/hr | |

| Engine Fuel Compatibility | DF1, DF2, B5, B20 | |

| Maximum Fuel Inlet Pressure | 180 kPa | |

| Cranking System | Unaided Cold Star——Minimum Cranking Speed | 120 RPM |

| Unaided Cold Star——Minimum Ambient Temperature For Unaided Cold Start | 12 deg C | |

| Unaided Cold Star——Breakaway Torque At Minimum Unaided Cold Start Temperature | 350 N.m | |

| Aided Cold Start——Minimum Ambient Temperature With Grid Heater Only | 32 deg C | |

| Aided Cold Start——Minimum Ambient Temperature With Ether Only | 32 deg C | |

| Aided Cold Start——Minimum Ambient Temperature With Coolant And Lube Heater Only | 40 deg C | |

| Cold Starting Aids Available | Ether, Intake Manifold Heater, Block Heater, Oil Pan Heater |

|

| Maximum parasitic load at 10 deg F @ 750 RPM | 505 N.m | |

| ——END—— | ||

Note: All Above Data are Just for Reference, All Data Might Change Without Notices or Updates, Please Contact Our Sales Team to Confirm All Details Via WhatsApp or Email.

Engine Sale Manual

Installation Drawing

Installation Manual

Operation Manual

Parts Catalogue