A table of error codes and fault codes for 140E series

1. Product Overview & Market Status

- Volvo Construction Equipment (Volvo CE) is the absolute leader and inventor in the global articulated hauler market, with its market share consistently ranking first worldwide (accounting for approximately 40%-50% or even higher).

- In 1966, Volvo CE officially launched the articulated hauler concept globally, pioneering an entirely new articulated hauler market. The year 2026 marks the 60th anniversary of the advent of this concept.

- The A-Series (including but not limited to A25, A30, A35, A40, A45) is the core product line of Volvo articulated haulers, covering the most mainstream medium and large-tonnage models in the global market. Among them, the A45 (previous model: A40D) is the best-selling model in the A-Series, with a rated payload of 45 tons. This payload capacity is in strong demand in large-scale mines, hydropower projects, and infrastructure projects.

- According to incomplete statistics, the global annual sales volume of Volvo articulated haulers is estimated at several thousand units. As a flagship model, the annual sales volume of the A45 is projected to be around several hundred to one thousand units

- Key Sales Regions: Europe, North America, and Australia are traditional advantageous markets; a considerable number of long-term customers in large-scale mines and engineering projects in China, Southeast Asia (Indonesia, Thailand, Vietnam), Africa, and South America also maintain continuous purchases.

2. Upgrade History & Current Challenges of A45 Series

- At bauma Munich 2017 in Germany, Volvo CE officially launched the all-new G-Series articulated haulers, including the A45G, which represents a significant upgrade from the previous F-Series (A40F/A45F launched around 2013).

-

To date, the first-generation models of the A45 Series have been on the market for over a decade, and many old units have entered the overhaul cycle. Several early A45G units purchased by large domestic mining enterprises have been used for remanufacturing

-

For the remanufacturing of an old A45, many key components need to be ordered from foreign manufacturers, resulting in high costs, long lead times, and insufficient standards. Whether the overall performance of the delivered vehicle meets customer expectations and the effectiveness of subsequent use remain to be further investigated.

3. Necessity & Advantages of Oil-to-Electric Conversion

- For A40/A45 articulated haulers operating under heavy-load downhill conditions or short-distance heavy-load uphill conditions, if the mining area’s power supply conditions can support the installation of high-power charging piles, “oil-to-electric conversion” can be fully considered as a priority option for discussion during overhaul decision-making.

By removing cost-intensive components such as engines and gearboxes, this not only directly achieves a significant reduction in operating costs and carbon emissions but also enables the project to be built into a new energy equipment technological transformation demonstration for the mining area, setting a new benchmark for green mine construction.

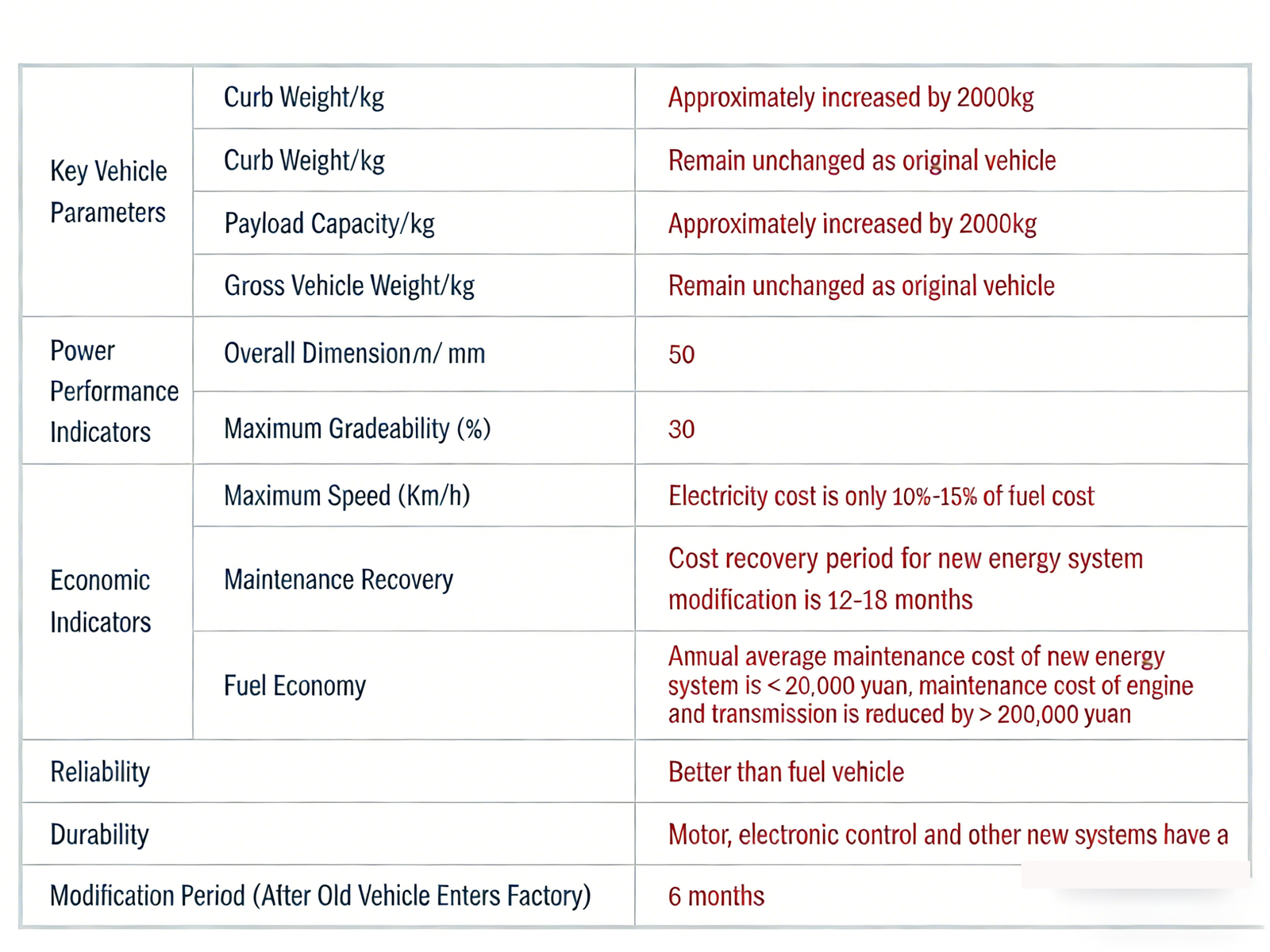

A40/A45 Electrification Technical Transformation Solution

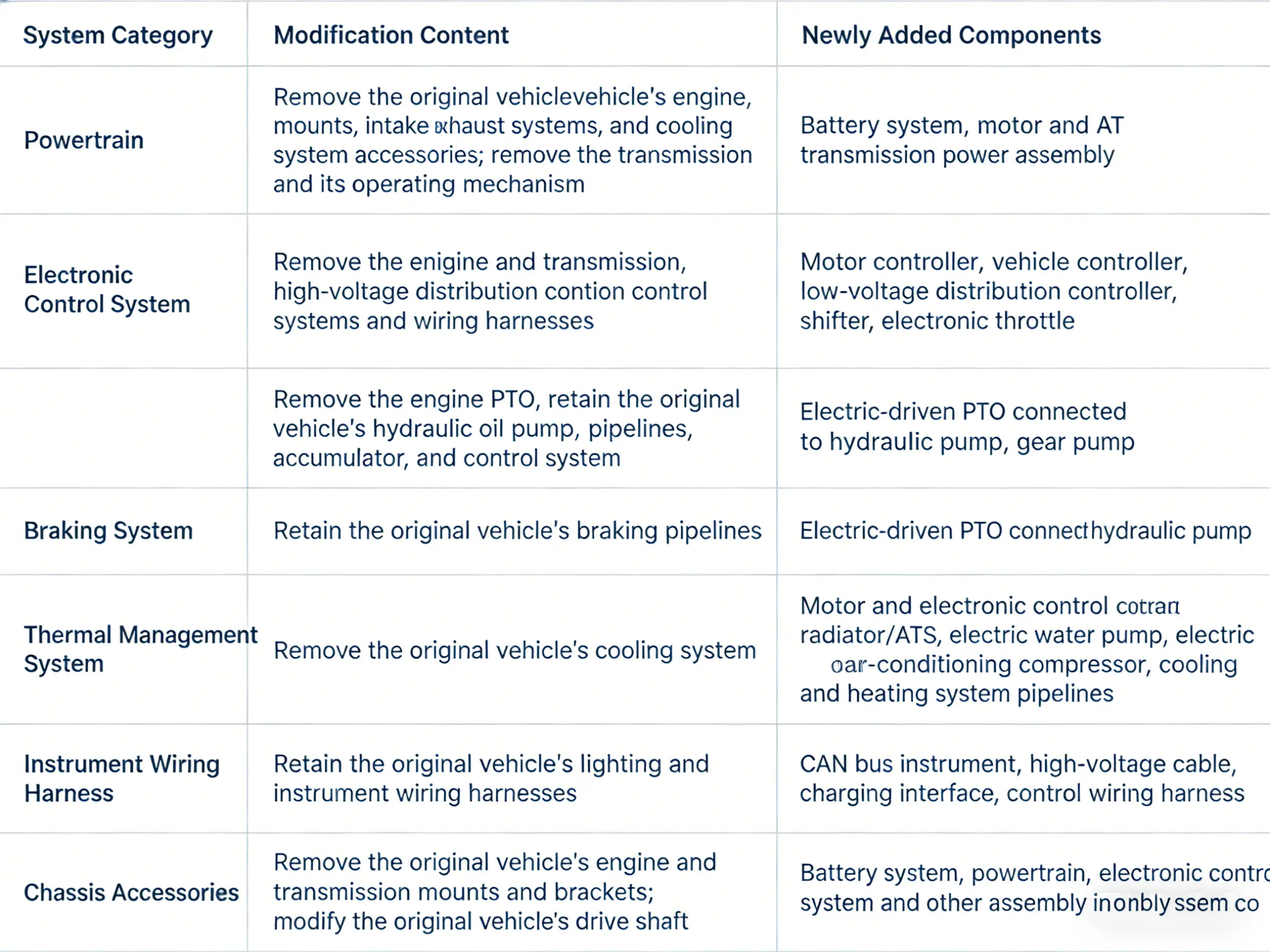

4. Overall Oil-to-Electric Conversion Solution

- In response to the electrification trend of mining equipment such as mining trucks and articulated haulers, domestic technology enterprises have made forward-looking layouts and taken the lead in developing mature and reliable overall “oil-to-electric conversion” solutions.

- This solution is developed in depth based on the A40 model, has completed technical verification, and features high platform expansion capabilities, which can be seamlessly adapted to A45 and other models on the same platform. It is now publicly available to the industry for evaluation and reference by industry partners.

- If there is a definite intention for conversion, we welcome further communication, and we will optimize the specific implementation plan for you. After all, knowledge gained from books is superficial; the success of project implementation relies on mutual cooperation.

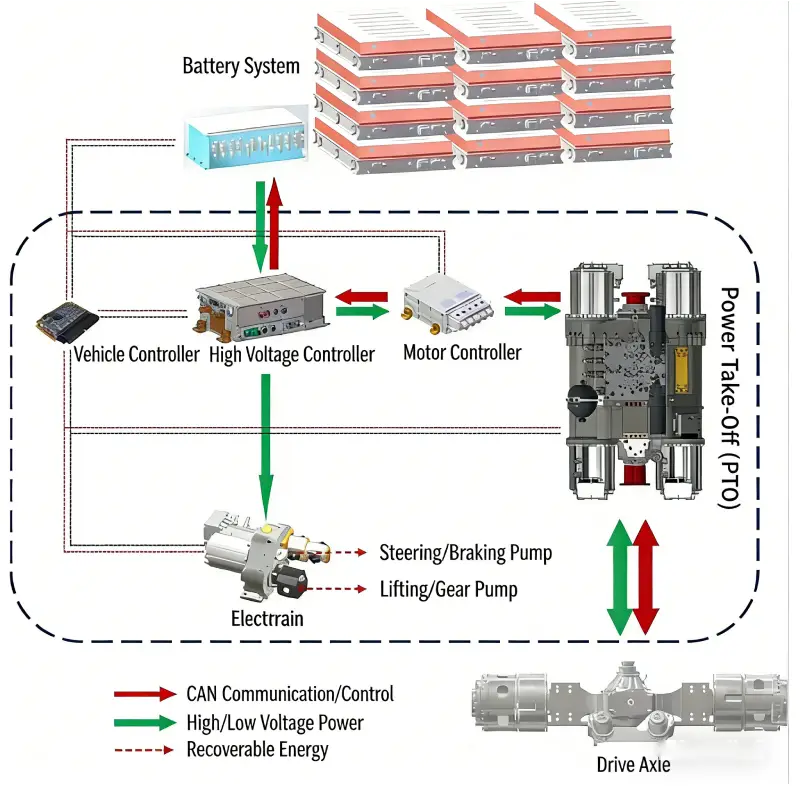

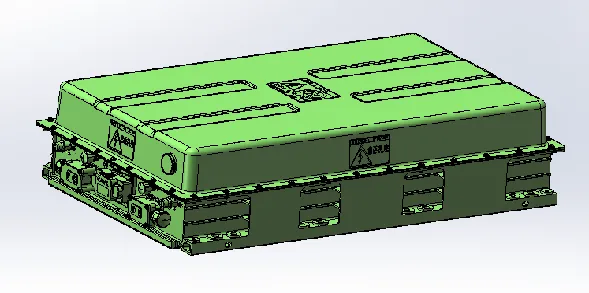

4.1 Key Parameters of the Vehicle Power Battery

- Total power of the power battery: 396kWh, composed of 12 standard T-type boxes; Rated voltage: 579.6V; Weight: approximately 2800kg (single electrical box weighs 230kg).

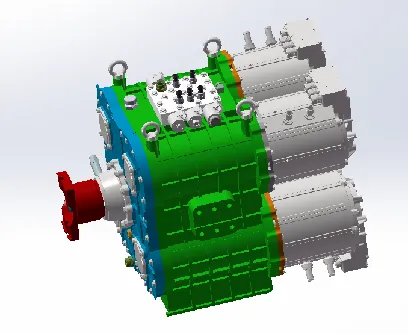

Core Components

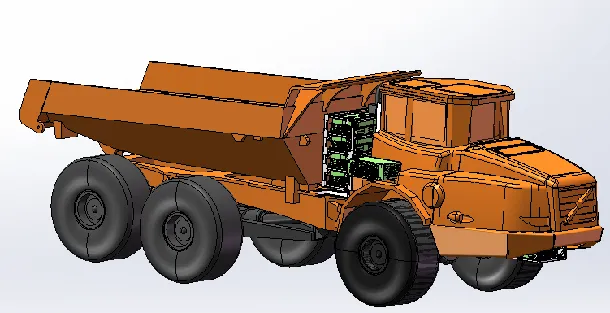

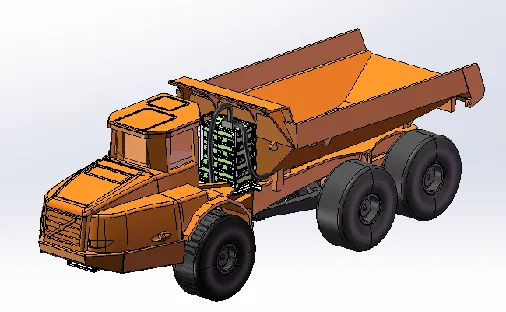

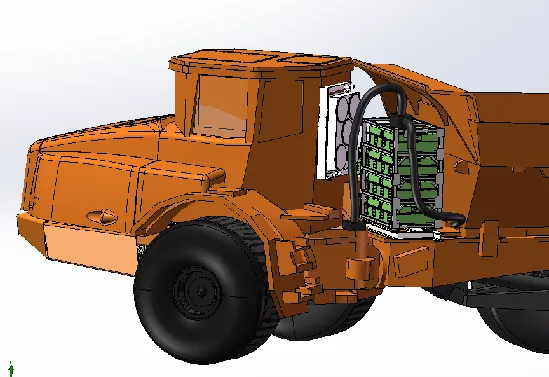

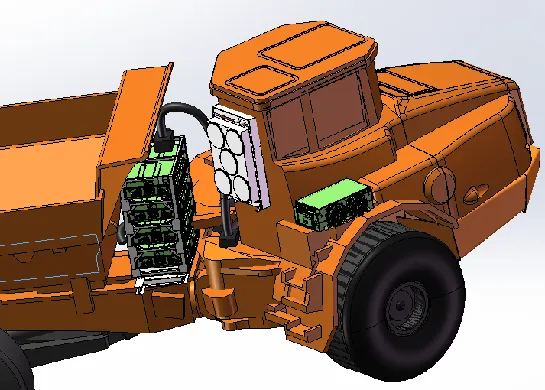

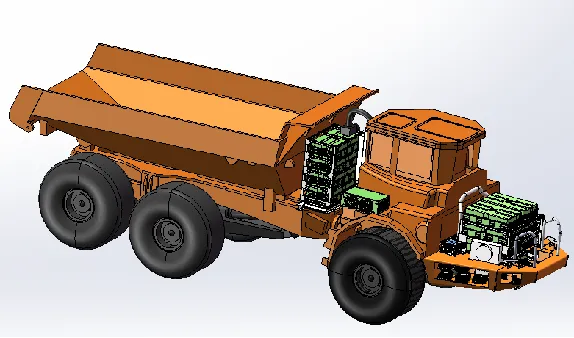

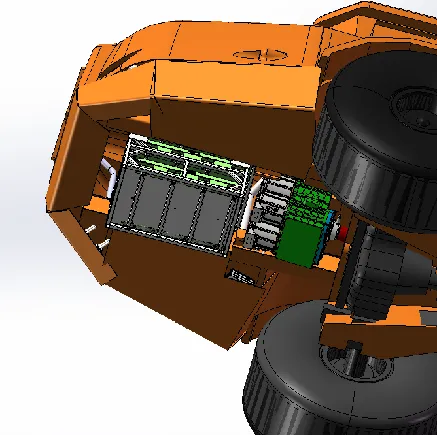

Rendering of the Retrofit Effect

Battery Pack Placement Position

Electric Drive System Installation Position

Rendering of 3-Speed Transmission + Four-Motor Configuration

Power Battery

5. Conclusion & Outlook

- As a star product with a large market ownership, solid customer base, and long service cycle (usually more than 10 years), the development of an “oil-to-electric conversion” technical solution for the A40/A45 has significant market potential and demonstration effect. It can cover a large number of high-end customers seeking updates to core equipment components and emission reduction.

- The essence of implementing oil-to-electric conversion for Volvo articulated haulers is to conduct a thorough power chain upgrade and replacement while retaining its unparalleled mechanical structure (frame, articulation, suspension) and operating experience (cab, control system).

- A successful “oil-to-electric conversion” solution will not only achieve zero emissions but also create total cost of ownership advantages and production efficiency that surpass the original diesel models through instantaneous torque, precise control, low noise, and low maintenance costs brought by electrification, while greatly extending the full life cycle of high-value fixed assets.